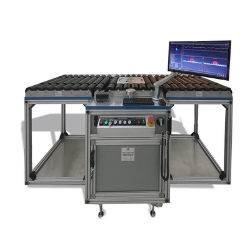

Magnetic Particle Flaw Detector NOVOTEST MPD-17P

Inhouse product

-

৳12,300.00

৳13,500.00

Reviews & Ratings

Magnetic Particle Flaw Detector NOVOTEST MPD-17P

The NOVOTEST MPD-17P is a high-performance Magnetic Particle Flaw Detector designed for the inspection of ferromagnetic materials. This portable and easy-to-use device is ideal for identifying surface and near-surface defects such as cracks, inclusions, and porosity in metals, ensuring the integrity of critical parts in industries like aerospace, automotive, and manufacturing.

Key Features:

Advanced Magnetic Particle Testing: The NOVOTEST MPD-17P uses magnetic particle inspection (MPI) to detect surface and subsurface flaws in ferromagnetic materials. The device magnetizes the object being tested and uses magnetic particles to highlight defects, ensuring accurate and reliable results.

Portable and Lightweight: The compact design makes it easy to carry and operate in various testing environments, both on-site and in remote locations. It is ideal for use in industrial plants, workshops, and maintenance inspections.

Multiple Operating Modes: The device offers several magnetization methods, including continuous, residual, and pulsed, for different testing requirements and material types, ensuring versatility in flaw detection.

Durable Construction: Built to withstand harsh industrial environments, the NOVOTEST MPD-17P is robust, resistant to dust, and capable of functioning in challenging conditions such as high humidity or low temperatures.

Clear and Easy-to-Read Display: The user-friendly interface and clear display allow operators to easily monitor and assess the results of their inspections, even in low-light conditions.

Efficient and Cost-Effective: The NOVOTEST MPD-17P allows for fast, non-destructive testing with minimal preparation, saving both time and money while ensuring high-quality inspections.

Applications:

- Inspection of castings, forgings, and welded parts.

- Quality control in the automotive, aerospace, and manufacturing sectors.

- Ensuring safety and reliability in critical structural components.

Frequently Bought Products

Siemens SOMATOM Go

Smartscan FA (Aircraft Wheel Inspection System) Automated System equipped with Eddycon D and PC

A1610 BONDVISOR( Flaw Detector For Bonded & Laminated Component and Honey-Comb Structure)

А1211 Mini Tiny Ultrasonic Flaw Detector

A1550 Introvisor TFM phased Army Ultrasonic Flaw Detector

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00