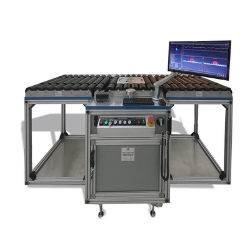

A1550 Introvisor TFM phased Army Ultrasonic Flaw Detector

Inhouse product

-

৳12,300.00

৳13,500.00

Reviews & Ratings

A1550 Introvisor TFM phased Army Ultrasonic Flaw Detector

The A1550 Introvisor TFM Phased Array Ultrasonic Flaw Detector is a state-of-the-art instrument designed for advanced flaw detection and precise thickness measurements in various materials, including ferrous and nonferrous metals, plastics, and weld joints. With cutting-edge Total Focusing Method (TFM) technology and phased array capabilities, it provides unmatched accuracy and reliability for industrial applications.

Key Features:

Material Versatility:

Capable of inspecting pipes, weld joints, and structural components made from ferrous and nonferrous metals, as well as plastics.Advanced Flaw Detection:

Identifies and sizes corrosion, cracks, delaminations, foreign inclusions, and other internal flaws, ensuring the integrity of critical components.High-Resolution Imaging:

Equipped with TFM phased array technology, the device generates detailed visual representations of the internal structure, aiding in precise evaluation.Thickness Measurement:

Provides accurate thickness readings, making it ideal for applications requiring precision monitoring of material wear or degradation.User-Friendly Operation:

Features an intuitive interface and customizable settings, enabling operators of all skill levels to perform inspections efficiently.Durability and Portability:

Designed for rugged environments, the compact and lightweight build ensures easy handling during on-site inspections.Comprehensive Analysis Tools:

Includes built-in data recording, analysis, and reporting features, with advanced capabilities like Digital TCG, DAC, and DGS diagrams for detailed assessment.

Applications:

- Industrial Quality Control: Inspect weld joints, pipelines, and structural components for flaws and ensure compliance with safety standards.

- Corrosion Monitoring: Detect and monitor the progression of corrosion in critical systems.

- Pipeline Maintenance: Evaluate the integrity of piping systems in the oil, gas, and chemical industries.

- Manufacturing: Ensure product quality by detecting inclusions, cracks, and delaminations during production.

- Aerospace and Automotive: Conduct detailed inspections of lightweight materials and complex assemblies.

Frequently Bought Products

Siemens SOMATOM Go

Klein Tools Kit

NOVOTEST UD2303 (Ultrasonic Flaw Detector )

Sonocon BL (Ultrasonic Flaw Detector and Thickness Gauge)

Eddycon CL (Eddy-Current Flaw Detector)

Parker Hydraulic Hose

Smartscan FA (Aircraft Wheel Inspection System) Automated System equipped with Eddycon D and PC

A1214 EXPERT Durable Ultrasonic Flaw Detector

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00