Eddycon CL (Eddy-Current Flaw Detector)

Inhouse product

-

৳12,300.00

৳13,500.00

Reviews & Ratings

Eddycon CL (Eddy-Current Flaw Detector)

The Eddycon CL is an advanced eddy-current flaw detector designed for precise, non-destructive testing (NDT) applications. It is ideal for identifying surface and subsurface defects, such as cracks, corrosion, and other material imperfections in metals and conductive materials. This lightweight and portable device is perfect for on-site inspections and laboratory use.

Key Features

- High Sensitivity: Accurately detects flaws in conductive materials, including aluminum, steel, and other alloys.

- User-Friendly Interface: Intuitive design with a clear display and easy-to-navigate menu for quick operation.

- Multi-Functionality: Supports a variety of testing methods, including defect detection, conductivity measurement, and material sorting.

- Advanced Data Analysis: Offers real-time signal processing, data storage, and comprehensive reporting features.

- Portable Design: Compact and lightweight for easy transportation and use in confined or hard-to-reach spaces.

- Customizable Settings: Adjustable frequency and gain for tailored inspection requirements.

Applications

- Surface and subsurface defect detection.

- Inspection of weld joints, pipes, and tubes.

- Material sorting based on conductivity.

- Corrosion detection in critical components.

- Routine quality control and maintenance checks in aerospace, automotive, and manufacturing industries.

Benefits

- Enhances safety and reliability by detecting flaws early.

- Saves time and cost with efficient and accurate testing.

- Suitable for operators of all skill levels with minimal training.

- Supports a wide range of inspection scenarios, making it versatile for multiple industries.

Frequently Bought Products

NOVOTEST UD2303 (Ultrasonic Flaw Detector )

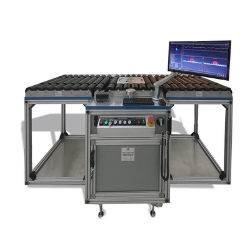

Smartscan FA (Aircraft Wheel Inspection System) Automated System equipped with Eddycon D and PC

Klein Tools Kit

NOVOTEST UD3701 (Ultrasonic Flaw Detector}

Parker Hydraulic Hose

A1610 BONDVISOR( Flaw Detector For Bonded & Laminated Component and Honey-Comb Structure)

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00