Brick Making Machine

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

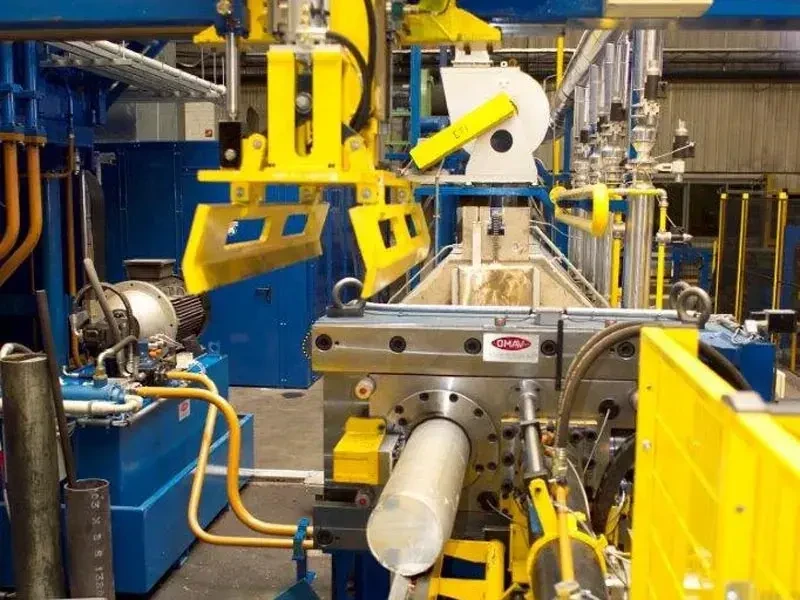

The brick making machine is a robust industrial device used to produce a wide variety of construction bricks using raw materials such as clay, cement, concrete, sand, fly ash, and soil. It plays a key role in modern construction and infrastructure development, providing efficient, cost-effective, and scalable brick manufacturing solutions. Designed for continuous operation, these machines are available in manual, semi-automatic, and fully automatic configurations to suit small-scale startups, medium-sized construction companies, and large industrial brick production plants.

The machine compresses raw materials into uniform brick shapes using hydraulic, mechanical, or vibration-based systems. Some models feature automatic feeding, molding, and stacking systems to streamline the production cycle and minimize labor input. Advanced machines include programmable logic controllers (PLC), touch-screen operation panels, and mold-changing systems to produce various sizes and shapes of bricks such as solid bricks, hollow blocks, interlocking bricks, and pavers.

Brick making machines are commonly used in the production of clay bricks, fly ash bricks, cement bricks, and interlock paving blocks. The equipment supports different forming methods such as hydraulic pressing, vibrating compaction, or extrusion, depending on the required output and material type. The machine body is made of high-grade steel for long-term durability and precision alignment during pressing.

Features:

-

Suitable for clay, concrete, cement, and fly ash brick production

-

Manual, semi-automatic, and fully automatic variants

-

Hydraulic or vibration compression for high-strength bricks

-

Interchangeable molds for different brick types and sizes

-

High-output capacity with low energy consumption

-

Mold-lifting system and automated stacking (for advanced models)

-

Reinforced steel frame for structural stability and precision

-

User-friendly interface with PLC control system (optional)

-

Compact design available for small-scale projects

-

Easy maintenance and long operational life

Technical Specifications (Typical):

-

Production Capacity: 500 to 10,000 bricks per hour (varies by model)

-

Power Requirement: 5 HP to 40 HP (based on configuration)

-

Brick Size Range: Standard, custom, and interlock options

-

Machine Type: Manual, hydraulic, vibrating, automatic

-

Operation Mode: Stationary or mobile

-

Raw Material Compatibility: Clay, fly ash, sand, cement, stone dust, lime

-

Molding Pressure: Up to 100 tons for high-density bricks

-

Automation: Optional belt conveyor, mixer, and stacking unit

-

Tolerance Level: ±1 mm dimensional accuracy

Applications:

-

Commercial and residential construction brick production

-

Infrastructure development (roads, pavements, drains)

-

Low-cost housing and rural development projects

-

Urban redevelopment and building restoration

-

Block and interlocking brick production for landscaping

-

Export-oriented brick manufacturing for large-scale markets

Frequently Bought Products

355mm 14” Cut off Saw Machine 2300W

ABS Coating Line

Forklift

Glass Tempering Furnace

Wire Drawing Machine

Screw Making Machine

Hot Log Shear

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00