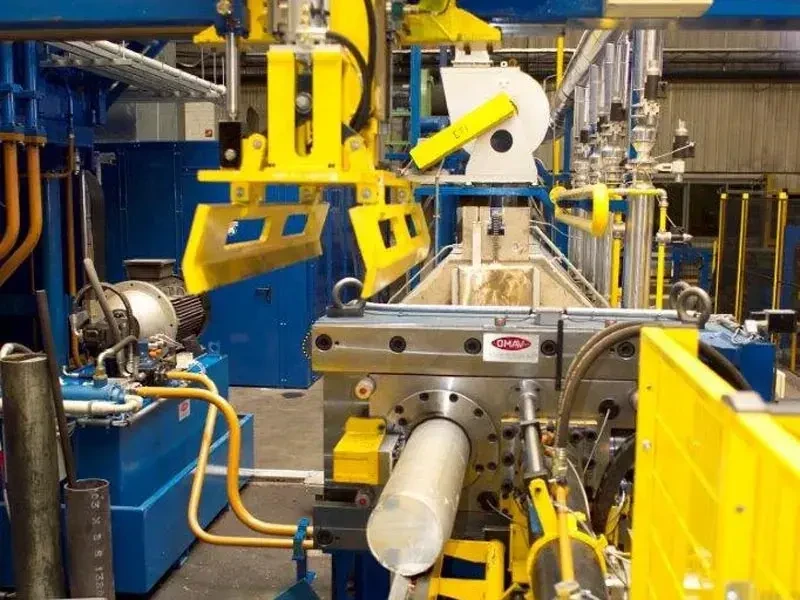

Annealing Furnace

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

An Annealing Furnace is a type of heat treatment equipment used to heat materials, typically metals or glass, to a specific temperature and then cool them gradually to alter their physical and mechanical properties. The annealing process is essential for relieving internal stresses, improving ductility, reducing hardness, and enhancing the overall quality of the material. Annealing furnaces are commonly used in industries such as metallurgy, manufacturing, and glass production.

Key Features:

Precise Temperature Control: Equipped with advanced temperature control systems, including digital or programmable controllers, to maintain accurate and consistent temperatures throughout the annealing process.

Uniform Heat Distribution: Designed to ensure even heat distribution within the furnace chamber, preventing temperature gradients and ensuring consistent treatment of all materials.

High-Temperature Capability: Capable of reaching and maintaining high temperatures necessary for effective annealing, with temperature ranges typically from 200°C to 1200°C (392°F to 2192°F), depending on the application.

Efficient Heating Elements: Utilizes high-quality heating elements such as electric resistive heaters or gas burners, designed for durability and efficiency in delivering the required heat.

Cooling System: Includes controlled cooling mechanisms, such as forced air or water cooling, to gradually and uniformly lower the temperature of the material, avoiding thermal shock and ensuring optimal material properties.

Customizable Chamber Sizes: Available in various chamber sizes and configurations to accommodate different material sizes and quantities, providing flexibility for various production needs.

Load Handling Systems: Features mechanisms such as trolleys, conveyors, or lifting systems for easy loading and unloading of materials, enhancing operational efficiency.

Safety Features: Equipped with safety mechanisms such as over-temperature protection, emergency shut-off systems, and safety interlocks to ensure safe operation and protect operators.

Frequently Bought Products

Embossing Machine

Hot Log Shear

Die Casting Machine

Slitting Machine

HF Pipe Making Machine

Brick Making Machine

SS Pipe Making Machine

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00