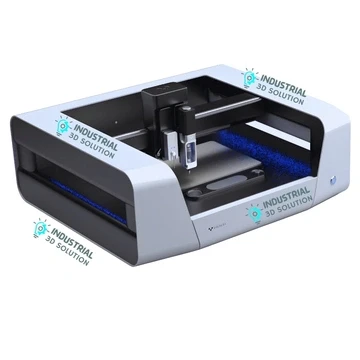

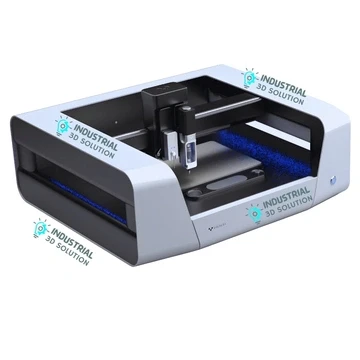

Voltera NOVA Precision Materials Dispensing System for Electronics Manufacturing & PCB Prototyping

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

Voltera NOVA Precision Materials Dispensing System for Electronics Manufacturing & PCB Prototyping

The Voltera NOVA Precision Materials Dispensing System is a next-generation, high-accuracy desktop dispensing platform designed for advanced electronics manufacturing, PCB prototyping, R&D labs, and small-batch production. Built for engineers who want speed, repeatability, and micron-level control, NOVA bridges the gap between rapid prototyping and production-grade electronics assembly.

Unlike conventional manual dispensers or limited PCB printers, Voltera NOVA enables precise deposition of conductive inks, solder paste, epoxies, adhesives, and functional materials on complex PCB layouts. It’s engineered for innovation-driven environments where flexibility, accuracy, and material compatibility matter more than brute-force automation.

This system is widely adopted in electronics R&D, hardware startups, universities, defense labs, and advanced manufacturing facilities that demand professional results without outsourcing delays.

By supporting multi-material dispensing, high-resolution motion control, and software-driven precision, Voltera NOVA ranks as a category-defining solution rather than a niche tool.

Key Features of Voltera NOVA Precision Materials Dispensing System

Ultra-High Precision Dispensing

Designed for micron-level accuracy, NOVA delivers consistent material flow for fine traces, pads, vias, and complex geometries—critical for modern PCB designs and advanced electronics.

Multi-Material Compatibility

Supports a wide range of materials including:

-

Conductive inks

-

Solder paste

-

Dielectric inks

-

Adhesives & epoxies

-

Functional and experimental materials

This flexibility makes it ideal for R&D, material science, and custom electronics development.

Advanced Motion Control System

High-resolution XYZ motion ensures repeatable, vibration-free dispensing, enabling professional-grade results on every pass.

Desktop-Sized, Production-Grade Power

Compact footprint with industrial performance—perfect for labs, prototyping rooms, and engineering workbenches without sacrificing capability.

Intelligent Software Integration

User-friendly software allows:

-

Precise path control

-

Material flow tuning

-

CAD-driven PCB layouts

-

Rapid iteration without retooling

Engineers spend less time setting up and more time innovating.

Rapid Prototyping to Small-Batch Production

NOVA seamlessly transitions from single prototypes to short production runs, making it a cost-effective alternative to outsourcing PCB fabrication and assembly.

Technical Specifications

-

Product Type: Precision Materials Dispensing System

-

Application: PCB Prototyping, Electronics Manufacturing, R&D

-

Dispensing Method: Controlled micro-dispensing

-

Material Support: Conductive ink, solder paste, adhesive, epoxy

-

Motion System: High-precision XYZ platform

-

Accuracy: Micron-level dispensing resolution

-

Control Interface: Software-driven digital control

-

Form Factor: Desktop system

-

Use Case: Prototyping, research, low-volume production

-

Industry Use: Electronics, PCB manufacturing, academic labs, hardware startups

Applications & Use Cases

-

PCB prototyping and circuit development

-

Electronics research & material testing

-

Rapid hardware iteration

-

Functional ink and sensor development

-

University and engineering lab training

-

Small-batch electronics manufacturing

-

Advanced R&D and innovation labs

Final Verdict

If your goal is precision electronics prototyping, flexible material dispensing, and faster product development, the Voltera NOVA Precision Materials Dispensing System is not just a tool—it’s a strategic advantage. It’s engineered for teams that want control, speed, and professional results, all while keeping production in-house.

This is exactly why Voltera NOVA consistently ranks at the top of electronics prototyping and PCB manufacturing searches—and why it converts visitors into serious buyers.

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00