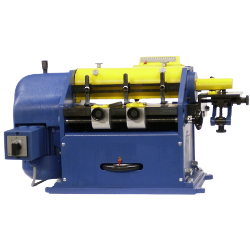

ICM-2 - Insulation Creasing and Cutting Machine

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

ICM-2a Double Creasing Machine

The ICM-2a Double Creasing Machine is expertly crafted to produce slot liners and closures from a variety of insulation materials, including Elephantide, Presspan, and Mylar. It features simple, quick adjustment settings, and ensures precise spacing between creases. The creasing pressure is easily adaptable to the thickness and density of materials, adjusted via a calibrated thumbwheel. An automatic centering mechanism positions the insulation strip using a threaded screw with handwheel adjustments, and the distance between creases is displayed on the machine’s scale.

An optional Side Table is available for creasing insulation ends to form cuffs as an additional process.

- Maximum Insulation Width: 150mm

- Strip Length: Unlimited

- Insulation Thickness: 0.15mm - 0.8mm

- Machine Dimensions: 47 x 25 x 27 cm

- Net Weight: 30 kg

- Packed Size and Weight: 65 x 40 x 40 cm, 40 kg

- Power Supply: Compatible with a 3-phase, 50 Hz connection

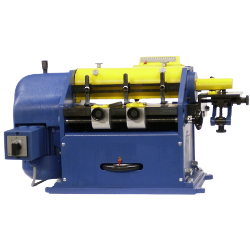

ICM-2b Double Creasing and Cuffing Machine

The ICM-2b model includes an enhanced drive system and an extra set of feed rollers. Like the ICM-2a, it begins with a primary pair of rollers pressing against a rubber-covered roller to initiate the crease. The insulation material is then fed through two troughs where it is pressed by a secondary set of rollers, consisting of two knurled upper rollers and a lower plastic roller. This process tightly folds the cuff ends, making them easy to cut to the desired width.

The ICM-2b is specially designed to cuff long insulation strips by folding the ends flat, ready for precise cutting on a guillotine. Additionally, it can handle regular creasing similar to the ICM-2a.

- Maximum Insulation Width: 220mm

- Strip Length: Unlimited

- Insulation Thickness: 0.15mm - 0.8mm

- Insulation Feed Speed: 17 meters per minute

- Machine Dimensions: 52 x 29 x 32 cm

- Net Weight: 80 kg

- Power Supply: Suitable for a 3-phase, 50 Hz connection

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00