DLPLC-601B Smart Electrician Comprehensive Training Platform

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

The DLPLC-601B Smart Electrician Comprehensive Training Platform is a professional-grade, modular training solution designed to equip students, technicians, and trainees with practical skills in industrial electrical systems, PLC programming, and automation technologies. Ideal for vocational institutions, technical universities, engineering departments, and industrial training centers, this platform simulates real-world scenarios in a controlled and safe environment.

Features

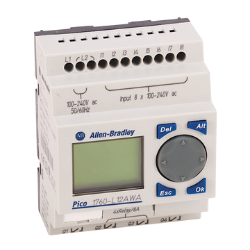

Integrated Programmable Logic Controller (PLC):

Includes a high-performance PLC unit for training in ladder logic, I/O signal processing, timers, counters, and program simulation.

Hands-on Electrical Circuit Design:

Features complete modules for learning basic to advanced electrical wiring, including switches, relays, sensors, contactors, indicator lights, and motor controllers.

Industrial Automation Simulation:

Enables learners to design, wire, and troubleshoot systems used in factory automation, production lines, and electrical distribution networks.

Smart Troubleshooting Functions:

Supports fault diagnosis and testing scenarios to enhance understanding of electrical failures, wiring mistakes, and safe recovery practices.

Durable, Modular Design:

Constructed with industrial-grade components built for repeat use in high-volume classroom or lab environments.

User-Centric Layout:

Clear labeling and intuitive module arrangement allow for easy setup, rapid prototyping, and independent experimentation by students.

Technical Training Areas Covered

-

PLC Programming (Digital/Analog I/O)

-

Basic and Advanced Electrical Wiring

-

Motor Control and Relay Logic

-

Sensor and Switch Configuration

-

Circuit Protection and Load Management

-

Industrial Automation Control Design

Ideal For

-

Technical and vocational institutes

-

Engineering colleges and polytechnics

-

Industrial training facilities

-

STEM and TVET education programs

-

Skill development in electrical and automation trades

Package Includes

-

DLPLC-601B Training Platform (fully assembled)

-

PLC module with necessary interface cables

-

Power supply and safety terminal blocks

-

Wiring and connection kits

-

Instructor manual and student training guide

Benefits

-

Combines multiple training disciplines into one streamlined system

-

Reduces instructional complexity with plug-and-learn modules

-

Bridges the gap between classroom theory and industrial practice

-

Enables both guided lessons and self-directed learning projects

The integrated technology of industrial control with programmable logic controller as the core has rapidly developed into a new subject in high and middle schools. Hands-on ability and the ability to cultivate students’ innovative ideas have formed an important backbone course for automation majors, mechatronics majors, and mechanical majors. The planning of the curriculum, supporting teaching materials, practice links, and laboratory construction of programmable logic controllers has received full attention from leaders at all levels and professional teachers.

“DPLLC-601B Intelligent Electrician Comprehensive Training Platform” is to meet the requirements of vocational education and practical training, the introduction of the German “dual system” education mode. Under the guidance of returned overseas students to introduce and absorb foreign advanced vocational training teaching equipment Finally, the programmable control training equipment that is closest to the industrial site is produced in strict accordance with the German teaching equipment (DIN) standard.

2.Training Contents

This system is suitable for learning and application training of programmable controllers for middle and senior vocational colleges and college students, as well as pre-job training for students and retraining for employees. It can not only meet the requirements of PLC experiment teaching and Relevant course design and assessment requirements can also be used as training equipment for engineering and technical personnel.

1). PLC training series such as usage and configuration of PLC software and PLC command learning

2). The training series based on HMI such as offline simulation application, project creation, editing and downloading operations, animation components application, system comprehensive application ect.

3). The inverter related training series such as parameter setting, multi-speed operation controlling, ect.

4). Wiring and debugging of inverter control motor

5). The control circuit training such as milling machine, boring machine, drilling machine, grinding machine, lathe, star delta, ect.

6). Contactor self-locking forward rotation control circuit

7). Contactor self-locking forward rotation control circuit with overload protection

8). Servo JOG electric debugging control

9). Servo PLC pulse control experiment

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00