Bambu Lab H2S Laser Full Combo Multi-Material High-Speed FDM 3D Printer with 10W Laser Module

Inhouse product

-

৳12,300.00

৳13,500.00 -

৳680.00

৳750.00

Before joining the group buy, please keep in mind the following:

- Group buy requires a minimum of 2 Orders

- Group buy price is ৳38800.00.

- Your payment will be charged right after the group is completed.

- The product will be delivered within 45 days after the group completion. But the delivery date could be extended.

- Ensure you are aware of the group buy terms and conditions before joining.

Reviews & Ratings

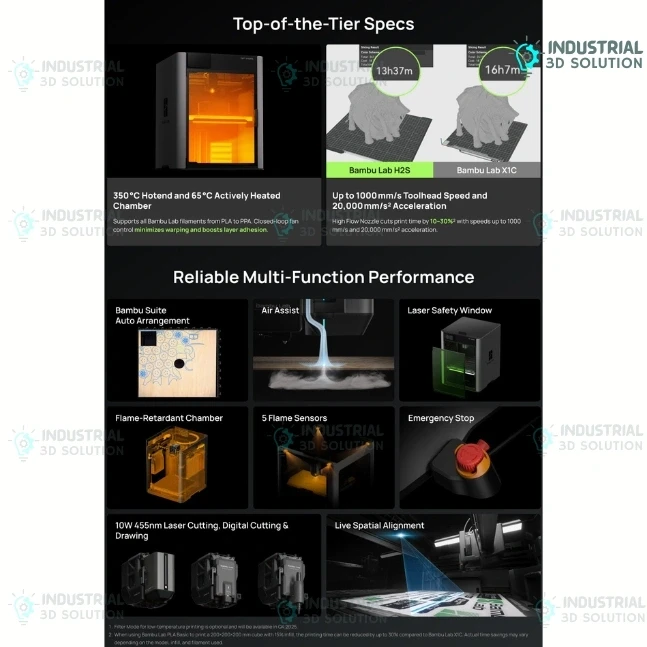

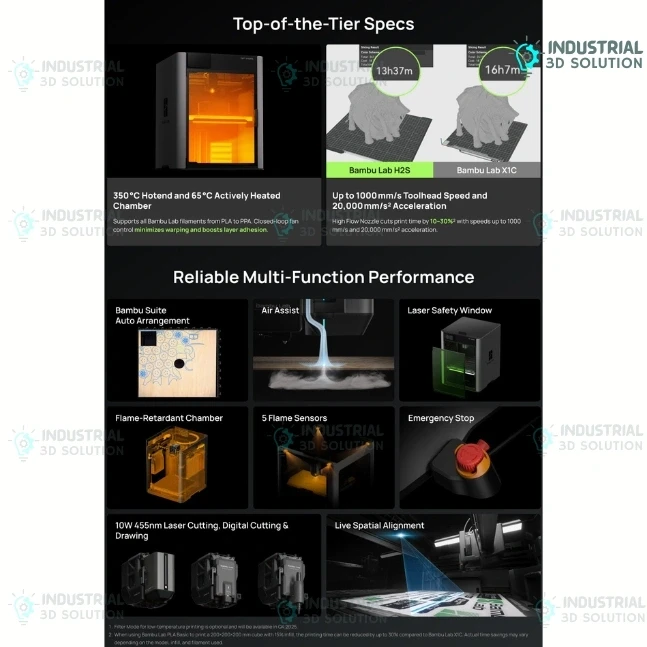

The Bambu Lab H2S Laser Full Combo is an advanced industrial desktop manufacturing system combining high-speed FDM 3D printing, multi-color material automation, and optional laser engraving/cutting capability in a single integrated platform. Designed for engineering workshops, production environments, research labs, and professional makers in Bangladesh, the H2S delivers a large 340 × 320 × 340 mm build volume, 350°C all-metal hotend, and AI-based filament monitoring for uninterrupted operation. Its closed-loop servo extruder system ensures consistent extrusion accuracy, while the optional 10W laser module expands the system into a hybrid fabrication solution capable of engraving and cutting compatible materials. With hardened steel extrusion components, active chamber heating, and industrial-grade chassis construction, the H2S Laser Full Combo offers a reliable, multi-purpose digital fabrication platform suitable for professional prototyping, manufacturing, and multi-material production workflows.

Key Features

• Large-format 340 × 320 × 340 mm build volume for professional industrial 3D printing

• Hybrid 3D printer with optional 10W laser engraving and cutting module capability

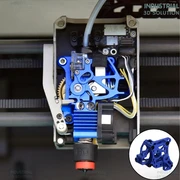

• Closed-loop servo motor extruder ensures high-precision filament control and consistent printing

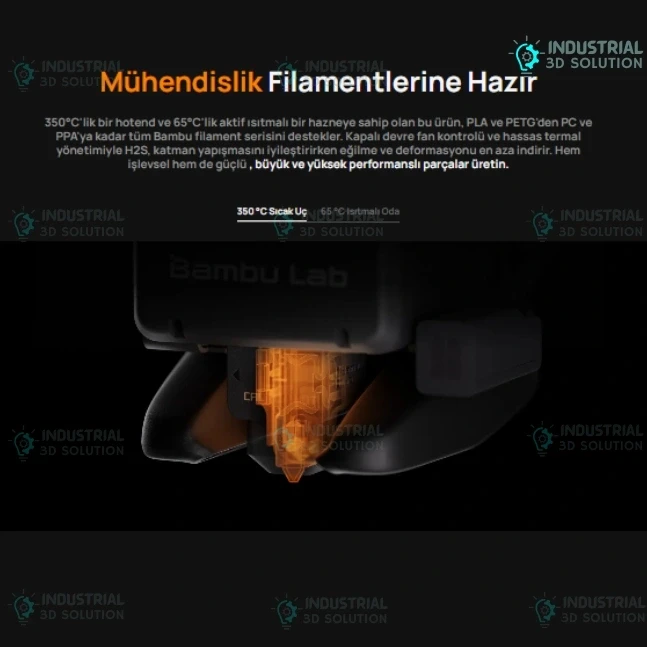

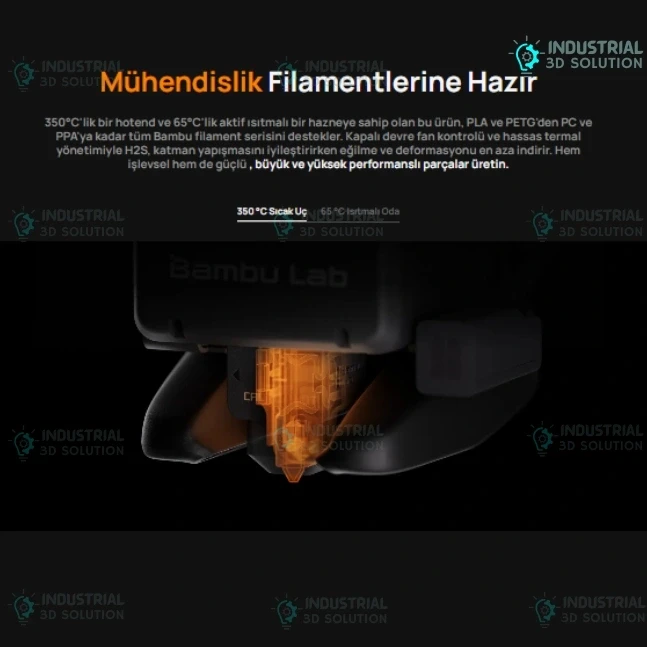

• 350°C all-metal hotend supports engineering-grade filament printing applications

• 65°C active heated chamber improves print reliability for ABS, Nylon, and technical materials

• Multi-color and multi-material printing compatibility using AMS automation system

• 5μm resolution optical motion calibration improves dimensional accuracy and repeatability

• Hardened steel extruder gears and nozzle designed for abrasive and carbon-fiber filaments

• Full filament path AI detection system enhances printing reliability and operational safety

Technical Specifications

Material / Model / Type: Bambu Lab H2S Laser Full Combo / Industrial Desktop FDM 3D Printer with Laser Module

Build Volume: 340 × 320 × 340 mm

Printing Technology: Fused Deposition Modeling (FDM)

Nozzle Type: Hardened Steel

Included Nozzle Diameter: 0.4 mm

Supported Nozzle Sizes: 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

Maximum Nozzle Temperature: 350 °C

Heated Chamber Temperature: Up to 65 °C

Laser Module: Optional 10W laser engraving and cutting module

Chassis Construction: Aluminum, Steel, Plastic, Glass

Compatibility: Bambu Lab AMS, AMS 2 Pro, AMS HT (4-in-1 PTFE Adapter required for multiple AMS units)

Operating Voltage: 100–120 V AC

Net Weight: 30.5 kg

Package Weight: 45.8 kg

Package Dimensions (L × W × H): 62 × 62 × 75.5 cm

Color / Finish: Industrial Black / Gray

Recommended Installation Space: 70 × 70 × 110 cm

Country of Origin: China

Applications / Use Cases

• Engineering prototype development and testing

• Industrial product design and functional part manufacturing

• Hybrid 3D printing and laser engraving fabrication workshops

• Educational institutions and research laboratories

• Signage and customization businesses

• Architectural modeling and design studios

• Professional maker spaces and production facilities in Bangladesh

Packaging Information

• Bambu Lab H2S 3D Printer (Laser Edition)

• AMS System (Full Combo configuration)

• 10W Laser Module and safety window assembly

• Standard hardened steel 0.4 mm nozzle

• Power cable, PTFE tubing, and installation accessories

• User manual and setup documentation

• Industrial-grade foam-protected secure shipping packaging

Why Choose This Product

• Hybrid manufacturing system combining 3D printing and laser fabrication capability

• Industrial-grade construction for long-term professional use

• Engineering material compatibility with high-temperature printing support

• Multi-material automation improves production efficiency

• Reliable availability, service, and technical support in Bangladesh

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00 -

৳680.00

৳750.00