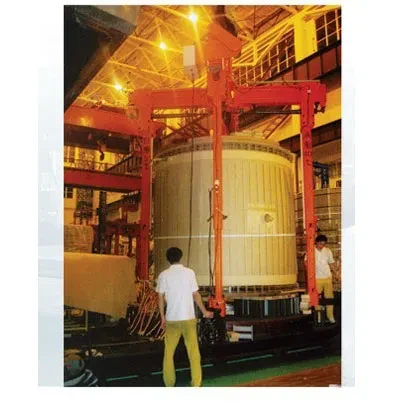

Fully Automatic Multi -trapezoidal Coils Winding Machine

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

The Automatic Parallel Winding Machine is a precision-engineered solution designed for high-efficiency winding of coils, wires, yarns, and flat conductors in a wide range of industrial applications. Ideal for use in transformer manufacturing, motor coil production, cable winding, and insulation tape processing, this machine delivers uniform, tension-controlled, and high-speed parallel winding for consistent quality and productivity.

Equipped with intelligent controls, adjustable tension systems, and automatic layer correction, the machine ensures smooth, parallel winding even on complex geometries or delicate materials. Its robust construction, user-friendly interface, and customization options make it suitable for both small-scale workshops and high-volume production environment

features

-

Precise Parallel Winding Technology

Delivers highly uniform and layer-accurate winding for round or flat wires, tapes, or filaments. -

Programmable CNC or PLC Control

Features an intuitive touchscreen interface with programmable winding parameters for easy operation and repeatability. -

High-Speed, Stable Performance

Capable of achieving high RPM while maintaining consistent tension, reducing cycle times without sacrificing quality. -

Adjustable Tension Control

Built-in servo or magnetic tension system ensures consistent tension for varying wire diameters and materials. -

Automatic Traverse Mechanism

Synchronizes with winding speed to ensure even layer distribution across the spool or coil body. -

Robust Construction

Heavy-duty frame with vibration-dampening technology supports long-term reliability in continuous-use environments. -

Customizable Spool Sizes and Wire Types

Supports multiple bobbin dimensions and compatible with copper, aluminum, enameled wires, and tapes. -

Low Maintenance Design

Uses precision bearings and modular components for easy servicing and long operating life.Applications

-

Transformer coil winding

-

Motor stator and rotor winding

-

Tape and yarn winding

-

Cable and conductor winding

-

Heating element and ignition coil winding

-

Electromagnetic and RF coil manufacturing

Technical Specifications

-

Winding Width: Up to 500 mm (customizable)

-

Wire Diameter Range: 0.05 mm – 5 mm

-

Spool Diameter: Up to 400 mm

-

Max Winding Speed: Up to 1500 RPM (material dependent)

-

Tension Control: Manual / Servo / Magnetic

-

Controller: PLC / CNC with HMI

-

Power Supply: 220V/380V, 3-phase, 50/60Hz

Designed to meet the high standards of modern industrial manufacturing, this machine offers exceptional reliability, precision, and speed. Whether you're producing fine coils for electronics or large conductors for transformers, this winding system ensures high-quality output with minimal material waste and downtime. Backed by expert support, training, and customization options, it's a long-term asset for any production environment.

-

-

Frequently Bought Products

Mobile Diesel Generator

IMOU HR12F AC1200 WIFI ROUTER

Transformer Coil Hanger

Vertical Winding Machine

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00