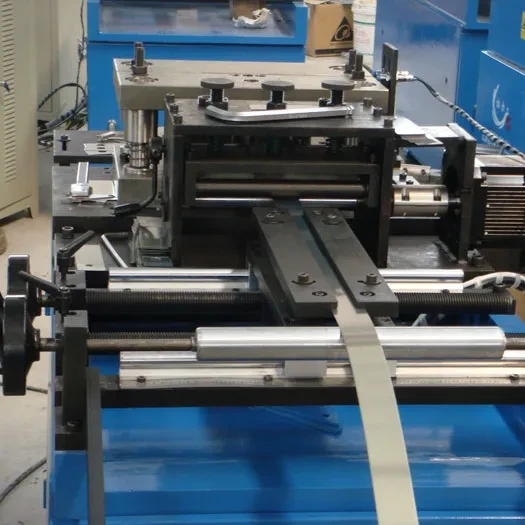

Digital Toroidal Winding Machine

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

The Digital Toroidal Winding Machine is an advanced, fully-automated solution for the precision winding of toroidal coils used in transformers, inductors, and current sensors. Designed for high-speed, high-accuracy production, this machine combines digital control systems with robust mechanical engineering to deliver consistent winding tension, perfect layering, and repeatable coil geometries for a wide range of wire gauges and core sizes.

Equipped with programmable logic control (PLC), touchscreen interface, and electronic tension management, the machine allows operators to input winding parameters with ease and store multiple coil programs for quick changeovers. It supports a wide variety of toroid types, including ferrite, powdered iron, and laminated cores, making it ideal for electronics manufacturers, transformer workshops, and industrial coil production lines.

Features:

-

Digital programmable control with memory storage for multiple coil designs

-

High-speed operation with accurate turns-counting and auto-stop functions

-

Electronic wire tension control for uniform winding across coil layers

-

Adjustable core holder for different toroidal core sizes and materials

-

Foot pedal and automatic start/stop functionality for user-friendly operation

-

Compact footprint and energy-efficient drive system

-

Real-time monitoring of winding progress and tension levels

Technical Specifications:

-

Winding speed: Up to 1,200 RPM (adjustable)

-

Core size range: Inner diameter from 10 mm to 300 mm (customizable)

-

Wire gauge support: 0.1 mm to 2.0 mm

-

Control system: PLC with digital display or touchscreen HMI

-

Power supply: 220V / 50Hz (custom voltages available)

-

Memory capacity: Up to 100 winding programs

-

Optional integration: Data logging, external I/O ports, remote diagnostics

Applications:

-

Toroidal power transformer manufacturing

-

Current sensing coil production

-

Inductors for power electronics

-

Audio transformer winding

-

Precision coils for telecommunications and instrumentation

Our machine is engineered for high-volume production and precision winding needs, ensuring minimal setup time, reduced manual intervention, and high repeatability. It helps manufacturers increase productivity, reduce errors, and achieve consistent product quality across batches. With customizable options and technical support, this machine is a future-ready investment for coil and transformer manufacturing.

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00