Cold Rolled Silicon Steel (CRGO & CRNGO) | Premium Grain Oriented & Non-Oriented Electrical Steel Sheets for Transformers & Motors

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

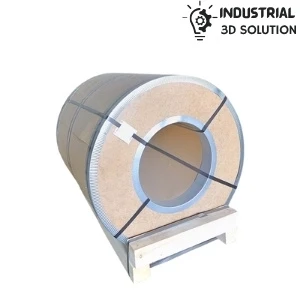

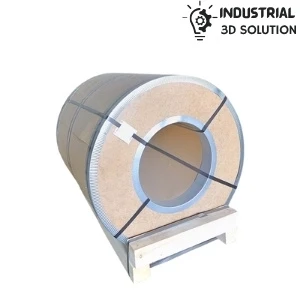

Cold rolled silicon steel is a specialized electrical steel widely used in the manufacturing of energy-efficient magnetic cores for transformers, motors, generators, and other electrical devices. Available in both grain oriented (CRGO) and non-grain oriented (CRNGO) grades, this steel is processed to deliver superior magnetic properties, reduced core loss, and high permeability.

Grain oriented electrical steel (CRGO) is specifically processed to align the grain structure in the rolling direction, providing excellent magnetic performance and low core losses, particularly ideal for power and distribution transformer cores. It ensures minimal energy loss during operation and is a preferred material in high-efficiency transformer applications.

Non-grain oriented electrical steel (CRNGO), on the other hand, has a random grain structure, offering uniform magnetic properties in all directions. It is used in rotating machines such as motors, generators, and alternators where multi-directional magnetic flux is required.

Manufactured through advanced cold rolling and annealing processes, cold rolled silicon steel meets international standards such as ASTM A876, IEC 60404, and JIS C2552. It is supplied in various grades, thicknesses, and coatings, including fully processed and semi-processed options, to suit both precision and high-volume applications.

Features:

-

Available in CRGO and CRNGO grades

-

Excellent magnetic permeability and low core loss

-

High electrical resistivity to reduce eddy current loss

-

Uniform thickness and smooth surface finish

-

Available with inorganic or organic insulation coatings

-

Supplied in coils, sheets, strips, or customized laminations

-

Thickness range: 0.18 mm to 0.65 mm

-

Compliant with international standards for electrical steels

Applications:

-

Power transformers

-

Distribution transformers

-

Electric motors

-

Generators

-

Reactors

-

Inductors

-

Magnetic core components

Technical Specifications:

-

Type: Cold Rolled Electrical Steel

-

Grades: CRGO (M3, M4, M5, M6), CRNGO (50A470, 50A600, etc.)

-

Thickness: 0.18 mm – 0.65 mm

-

Core Loss: As per grade (e.g., ≤1.3 W/kg at 1.5 T, 50 Hz)

-

Coatings: C5 (inorganic), C9 (organic), or customized

-

Form: Coils, slit coils, sheets, laminations

Cold rolled silicon steel is a critical material in modern energy systems, enabling the efficient conversion and transfer of electrical power with reduced energy loss. Its high magnetic performance, combined with mechanical stability and precision finish, makes it essential in the manufacture of high-performance electrical equipment across industries.

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00