Acetal(polyvinyl formal) Enameled Wire

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

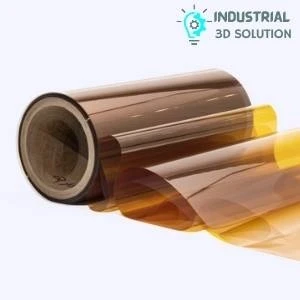

used extensively in electrical applications requiring excellent dielectric strength, thermal endurance, and mechanical stability. Coated with a durable layer of PVF enamel insulation, this wire delivers superior performance in high-speed winding, tight coil formations, and environments exposed to elevated temperatures.

Engineered for use in transformers, electric motors, relays, solenoids, and other electromagnetic devices, Acetal Enameled Wire offers a smooth surface, high thermal resistance, and exceptional mechanical toughness. Its enamel coating provides excellent adhesion, abrasion resistance, and compatibility with common electrical varnishes and impregnating resins.

Features:

-

Durable PVF Insulation: Provides strong resistance to mechanical wear and thermal degradation.

-

High Dielectric Strength: Ensures insulation reliability under high voltage conditions.

-

Thermal Class 105°C: Suitable for continuous operation in Class A thermal environments.

-

Superior Windability: Ideal for high-speed coil winding and automated production.

-

Excellent Adhesion: Ensures bond strength during varnishing or resin impregnation.

-

Low Friction Surface: Reduces damage and stress during tight winding applications.

-

Resistant to Solvents and Moisture: Enhances longevity in industrial environments.

Applications:

-

Transformer winding

-

Electric motor coils

-

Solenoids and electromagnets

-

Relays and sensors

-

Control coils and inductors

-

Automotive electrical components

-

Household and industrial appliance motors

Technical Specifications:

| Specification | Details |

|---|---|

| Conductor Material | Copper or Aluminum |

| Insulation Type | Polyvinyl Formal (Acetal) Enamel |

| Thermal Class | 105°C (Class A) |

| Diameter Range | 0.1 mm to 3.0 mm (customizable) |

| Dielectric Strength | High, based on IEC 60317 / NEMA standards |

| Adhesion & Flexibility | Excellent – withstands repeated winding stress |

| Standards Compliance | IEC 60317-8, NEMA MW 15-C, JIS C 3202 |

Frequently Bought Products

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00