Insulation Paper Folding Machine

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00

Reviews & Ratings

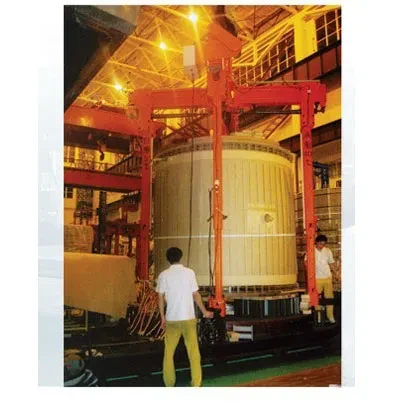

The insulation paper folding machine is a precision-engineered solution designed for folding insulation paper used in power transformer winding and coil production. Built for accuracy, speed, and durability, this machine enhances the efficiency of insulation layer formation, ensuring tight, uniform folds essential for high-voltage performance and safety.

Ideal for transformer manufacturing, repair workshops, and insulation material processing plants, the machine supports various types of dielectric paper, including crepe paper and DDP (diamond dotted paper), while delivering consistent, automated folding results.

Features:

-

Automatic Folding Mechanism: High-speed folding ensures uniform creases for insulation paper used in LV and HV transformer coils.

-

Adjustable Folding Width: Supports various insulation sizes to accommodate multiple transformer designs.

-

Precision Control System: Touchscreen or PLC interface allows real-time monitoring and customization of folding parameters.

-

High Efficiency: Increases output and reduces manual labor for bulk paper processing.

-

Heavy-Duty Construction: Built with durable components to ensure long-term reliability and minimal maintenance.

-

Material Compatibility: Suitable for a wide range of insulation materials, including kraft paper, crepe paper, and diamond dotted paper.

Applications:

-

Transformer insulation paper folding

-

Low-voltage and high-voltage coil insulation

-

Transformer manufacturing lines

-

Electrical equipment insulation processing

-

Dielectric paper folding for winding insulation

Technical Specifications:

| Parameter | Specification |

|---|---|

| Folding Width | 20 mm – 100 mm (adjustable) |

| Folding Speed | 0–30 m/min (variable) |

| Paper Type | Crepe paper, kraft paper, DDP |

| Control Interface | PLC / Touchscreen |

| Drive Type | Servo or Stepper motor |

| Power Supply | 380V / 50Hz (customizable) |

| Dimensions | As per machine model |

| Weight | Varies by configuration |

Frequently Bought Products

IMOU HR12F AC1200 WIFI ROUTER

Wound Core Machine

Transformer Coil Hanger

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00